Kaefer Energy

Implement new Prefabrication solution

We help our customers digitize their work processes

The solution supports a range of functions such as pricing and estimation, contract maintenance, quality control, logistics, invoicing and administration, post-production work and resource reporting. By streamlining Kaefer Energy’s processes and controlling data quality, the solution adds significant value to the business.

Using InVision – our business applications framework, we developed a solution for Kaefer Energy that streamlined its manufacturing processes and eliminated the use of a number of business-critical Excel spreadsheets.

The situation

Kaefer Energy is a leading multi-disciplinary company supporting Norway’s oil and gas industry. The company has a prefabrication workshop for steel and insulation products in Stavanger that supplies materials for all of the company’s projects.

Kaefer Energy puts the customer first

Kaefer Energy’s vision is to live up to customer expectations.

Solution-oriented and competence-based attitudes are fundamental to

meeting customer challenges in a confident and efficient manner. In

recent years, lean methodology has been developed and implemented

to create added value. This includes streamlining the manufacturing

process while ensuring quality, security, and customer needs in the best

possible way.

The challenge

Manual Processes

Due to the high competition in the market, Kaefer Energy had to develop an increasingly flexible and advanced pricing and estimation system for the prefabrication workshop. This was necessary, in order to handle different types of tender processes, contracts and production orders.

The employees had developed a system based on an Excel model, which was adjusted and customized as needed over time.

Kaefer realised that being dependent on the knowledge of individual employees with regards to the Excel model placed them in a vulnerable position. If the relevant employees became unavailable Kaefer would meet a significant risk.

Challenges with integration between systems

Improvement processes based on performance figures were difficult and time-consuming to implement. Excel’s decentralised storage model made it challenging to find, share, assemble and analyse data in a secure, efficient and reliable way. Challenges relating to maintenance, changes and further development of the model were also important factors influencing Kaefer Energy’s need for a more robust solution.

Furthermore, they met challenges regarding integration and exchanging data between the Excel model and Kaefer’s planned project management system. It involved manual work, which was both time-consuming and subject to human error.

The solution

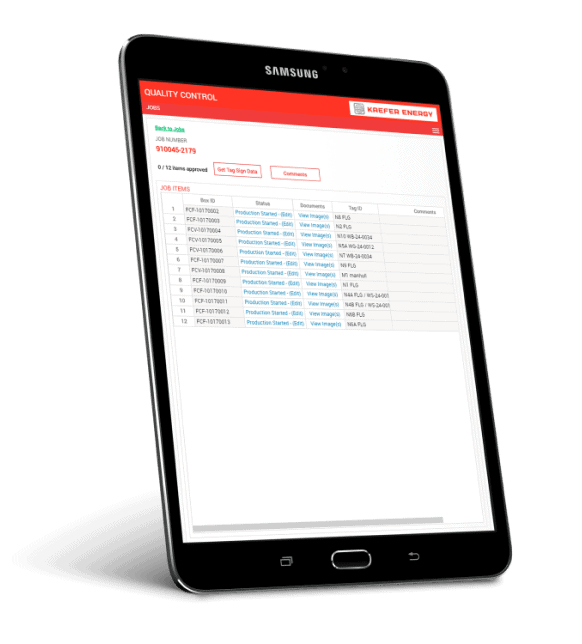

A new web-based solution

In collaboration with Kaefer Energy, Profitbase developed a web-based solution that replaced the Excel model’s functionality while also supporting the prefabrication workshop’s entire workflow from start to finish.

The new system is built on the Profitbase InVision platform, where users work in an intuitive interface customized to the various production roles and processes.

In addition to the pricing and estimation system, the following functions where included:

- Contract maintenance

- Quality control

- Logistics

- Invoicing

- Administrative post-production work such as resource reporting

The result

The introduction of the new system has made processes relating to contract, supply and production work easier, more efficient and robust. Kaefer Energy is no longer vulnerable with respect to the availability of critical personnel, system maintenance and development of own models. Resources previously used in these areas can now be utilised more effectively.

More efficient utilisation of resources

Reduced time spent on planning and administrative tasks, improved control and overview of resource consumption, and analytical possibilities enables Kaefer Energy to utilize its resources more efficiently and to increase its competitiveness.